The production of phytase from phytate through yeast cell modification has the potential to positively impact both bakeries in India and the health of the general public:

1. End-product:

Our intended end-product can be a wet yeast for direct use in smaller bakeries or dried yeast to be added for use for large scale bakeries; it can also be added into premixes as suggested by dietician Charolette Jhakaria, for traditional dishes like dosa or idli.

2. Public Health:

Nutrient Availability: Phytase can increase the bioavailability of essential minerals like phosphorus, iron, and zinc in baked goods, potentially addressing micronutrient deficiencies.

Healthier Diet: The enriched bread may contribute to a more nutritious diet, potentially benefiting the general public's health in the long run.

Overall, the yeast cell modification for phytase production has the potential to enhance bakery products and improve the nutritional content of daily diets, potentially benefiting both businesses and public health in India.

Enhancing the nutritional quality of livestock feed is a promising initiative with the potential to benefit consumers worldwide. By fortifying animal feed, we can ensure that the livestock raised for human consumption receive essential nutrients, ultimately improving the nutritional value of the meat and dairy products derived from them.

To adhere to regulatory guidelines, such as those outlined by the OECD, it is imperative to conduct rigorous assessments. This includes evaluating genotoxicity and health hazards associated with feed preparation. Additionally, a critical aspect is investigating the digestibility of supplemented feed. If incomplete digestion occurs, it is essential to demonstrate that any resulting metabolites are non-toxic and non-allergenic.

The outcome of these assessments will provide crucial insights into the key nutrients and potential toxicants present after supplementation, ensuring that the fortified livestock feed remains safe, nutritious, and beneficial for both animals and consumers alike.

Rules and regulations:

In India, the FSSAI is the food regulations authority which states the following prerequisites for the prior approval for manufacture, storage, distribution, sale and import etc.— (1) No person shall manufacture, pack, store, sell, market or otherwise distribute or import any food or food ingredient produced from GMOs, except with the prior approval of the Food Authority. (2) The provisions of these regulations are in addition to, and not in derogation of, any other rules or regulations made under the Act.

Procedure for grant of prior approval— (1) The food business operator (manufacturer/importer) of a GM-food shall submit an application as per the format prescribed by the Food Authority along with necessary documents and fee to the Food Authority. (2) If the application is for a GMO referred to as in clause (a) of sub-regulation (2) of regulation 1, clearance from Genetic Engineering Appraisal Committee (GEAC), the national competent authority for the environmental risk assessment shall be submitted to the Food Authority.

Our product will have to first receive clearance from GEAC.

If our intended final product receives a ‘Unique Identifier Nine-digit Code’ of the Organisation for Economic Cooperation and Development (OECD) that is approved for food use by the FSSAI, it will require no further approvals.

Our conversation with a policymaker, Dr Kapila Mehta

3. Implementation in bakery industry:

To overcome challenges related to the effects of fermentation on phytase and achieve desired outcomes, industries may need to implement various process optimizations. These optimizations can vary depending on the specific goals and challenges faced by each industry.

Here are some potential process optimizations:

Fermentation Conditions: Adjust fermentation conditions such as temperature, pH, and oxygen levels to create an environment conducive to phytase activity. This may involve optimizing these parameters for the specific microorganisms used.

Fermentation Duration: Optimize the duration of fermentation to balance the desired increase in phytase activity with the risk of enzyme inactivation over time. Monitoring enzyme activity throughout the process is crucial.

Enzyme Production: Develop strategies to enhance the production of phytase enzymes during fermentation. This might involve using inducers that stimulate enzyme production.

Co-Fermentation: Explore co-fermentation with microorganisms that produce organic acids or other compounds that can enhance phytase activity. This can create a more favourable environment for enzyme function.

Monitoring and Control: Implement robust monitoring and control systems to continuously assess phytase activity and adjust fermentation conditions in real-time. This can help maintain optimal enzyme activity throughout the process.

Impact on Bakeries in India:

- Improved Dough Quality: Phytase can enhance dough quality, leading to better texture and volume in baked goods like bread.

- Cost Savings: It can reduce the need for costly additives, resulting in more cost-effective bakery operations along with the prospects of employing simultaneous fermentation.

- Enhanced Product Portfolio: Bakeries may diversify their product offerings with improved quality, potentially attracting more customers.

4. Future iGEM teams:

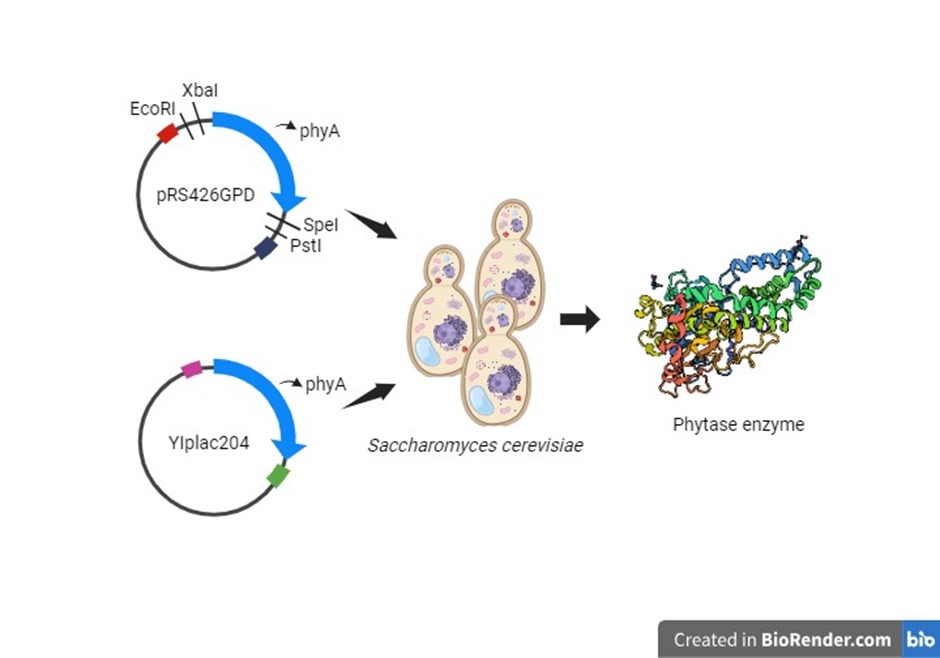

Future iGEM teams can play a pivotal role in fortifying essential nutrients in both human and animal food products by building upon our work as a foundational starting point. Our recombinant plasmid can be used to introduce genes for the synthesis of other nutrients like vitamins, to be transformed into microorganisms efficiently. iGEM teams can use this platform to engineer microorganisms for nutrient production and enhance the nutritional value of everyday foods through collaboration and innovative solutions. Our shared goal is to address global health challenges related to nutrition and improve public health by fortifying commonly consumed foods.

5. Safety:

Our project involves genetically modifying the yeast Saccharomyces cerevisiae to express the enzyme phytase. S. ce revisiae is classified as GRAS (generally regarded as safe), and the enzyme that is being overexpressed is not toxic.

We are using an auxotrophic marker (URA3) for transforming S. cerevisiae with an episomal plasmid containing the phytase gene. For genome integration too, an auxotrophic marker (TRP1) will be used. No antibiotic markers will be used.

However, as the plasmids we are using are E. coli-S. cerevisiae shuttle vectors, the bla gene (ampicillin antibiotic marker) is present in the vector. Integration of a linear DNA fragment containing just the expression cassette and an auxotrophic marker in the yeast genome is an approach which we plan to take once we have established proof of concept.

As the constructed yeast strain will be used for leavening breads, which are baked before consumption, we do not expect release of the modified organism in the environment.

References: [1] 50374/2022/REGULATION-FSSAI [2] OECD’s Report of the task force for the safety of novel foods and feeds [3] C. Frontela, G. Ros, C. Martínez, Phytic acid content and “in vitro” iron, calcium and zinc bioavailability in bakery products: The effect of processing, Journal of Cereal Science, Volume 54, Issue 1, 2011, Pages 173-179, ISSN 0733-5210, https://doi.org/10.1016/j.jcs.2011.02.015. [4] Nuobariene, L., Arneborg, N., & Hansen, Å. S. (2014). Phytase active yeasts isolated from bakery sourdoughs. In 9th Baltic Conference on Food Science and Technology "Food for Consumer Well-Being": FOODBALT 2014 - conference proceedings (pp. 223-227). Latvia University of Agriculture. Baltic Conference on Food Science and Technology